- Free Safety Program Templates

- Free Safety Programs For Construction

- Construction Safety Programs Free Downloads

Your overall occupational safety and health management system or safety program will include small 'p' programs that address specific hazards, as required by OSHA.

A health and safety checklist is a tool used to reinforce Workplace Health and Safety (WHS) practices and help organizations comply with safety rules and regulations. Performing regular inspections using health and safety checklist templates is a proactive approach to preventing work-related incidents, injuries, and illnesses. Health and Safety Departmental Guidelines This template allows local departmental health and safety guidelines to be developed. Working from Home Risk Assessment Checklist If an employee is required to work from home, then you still have a responsibility for their health and safety.

Once you identify the hazards of your workplace and the OSHA regulations that apply, you will know what programs you need.

You can download sample programs from this website for some of the most commonly needed programs. Adapt them to your organization --- make them work for you. SafetyWorks! can answer your questions and even come to your workplace to help you develop your programs.

View / Download Sample Safety Programs

Forklift Operator Checklist - Daily checklist for safe operation of forklifts

Performance Test for Forklift Operators - Form that allows the employer to evaluate forklift operators skills at the work site.

Ground Ladder Checklist - Checklist for safety inspection of ground ladders.

Qualitative Respirator Fit Test - Evaluates fit of respirators to ensure safe use.

Respiratory Plan for Fire Departments - This sample plan concerns respirator use in general industry and construction workplaces as regulated in 29 CFR §1910.134 .

General Respiratory Plan - Sample respiratory plan for general industry and construction workplaces (not for fire departments.)

Emergency Action Plan - Workplaces must have an emergency action plan to ensure employee safety in case of emergency. Companies with 10 or more employees must have this plan in writing.

Hazard Communication Plan - REVISED - Any workplace that has hazardous materials must have a written Hazard Communication program. Because most chemical products, even cleaning products, are consider hazardous, most workplaces need a Hazard Communication program. Revised program includes labeling changes under the Global Harmonization System.

Lockout Tagout form for Equipment - Forms for lockout/tagout procedures,programs and equipment.

Lockout / Tagout Procedures Inspection Form - At least annually an inspector will review the Hazardous Energy Control Procedure with all authorized employees and actually observe the use of the procedure.

Control of Hazardous Energy Sources (Lockout/Tagout) - Workplaces where employees do maintenance or repair work need a written Lockout/Tagout program to protect against unexpected startup of equipment.

Respiratory Protection Programs Checklist - Helps ensure your facility has met all requirements for a respiratory protection program.

Respirator Selection Checklist - Helps you select a respirator that is appropriate for the hazards present at the worksite.

Volunteer Firefighter Model Policy - Public Law 296 provides volunteer firefighters protection from discipline or discharge, in certain employment situations, on the grounds that the volunteer firefighter arrives late or does not arrive to work because the volunteer firefighter is responding to certain emergencies to which the fire department is called to respond. The law allows written agreements between employees and employers to supersede the terms of the proposed law. This model policy / agreement has been developed as an option for employers to use.

Respirator Fit Testing Checklist - Items that are required for employees who are using tight fitting respirator facepieces.

Respirator Program Evaluation Checklist - Checklist for program administrators to use.

Confined Space Permit Form (Sample One) - Guides employers and employees on the hazards that need to be assessed prior to entering a confined space.

Confined Space Permit Form (Sample Two) - Provides employers and employees with permits that are requied to enter PRCS. Air quality, rescue needs and addresses other hazards

Confined Space Alternate Procedure Checklist - Provides employors and employees with a list of hazards that need to assessed prior to entering a Confined Space other that a PRCS.

Safety Harness Inspection Checklist - Provides a safety checklist for fall protection body harnesses. Check stitching,D-rings and other critical items of harnesses and lanyards.

PPE Assessment Form Version 2 - Assist employers in training employees on PPE needs for a task. Provides area to document training.

Energized Electrical Work Permit - When live electrical must be performed all vested parties must be notified. All questions must be answered by the qualified electrician on this permit and turned over to the supervisor for approval.

Responding to Domestic Violence Abusers in the Workplace - This toolkit was designed to help employers and workers create a comprehensive response to domestic violence in the workplace.

Synthetic Sling Inspection Form -

Chain Sling Inspection Form -

Medical Evaluation Checklist - Checklist for administrators to use.

Chemical Hygiene Plan - Non-production laboratories where small scale chemical experiments are conducted must have a chemical hygiene plan, under OSHA's Laboratory Standard (29 CFR 1910.1450). This sample plan is for secondary schools.

Construction Jobsite Checklist - Checklists for Construction related exposures.

Fire Prevention Plans - Plan to assist employers in fire prevention.

Staging Checklist - Daily stationary staging checklist,

Fire Department and EMS Blood Borne Exposure Plan - Provides fire department and EMS with a guide for all areas that are required to be part of a BBP exposure plan.

Crane Inspection Form - Provides basic items on cranes that need to be inspected on a daily bases. (Hooks, steps, attachments, safety glass, drums ect..)

OSHA 300 Injury Reporting Forms - Provides OSHA 300, 300A Summary Form and 301 Forms

LOTO Lock Removal Procedure Form - Provides the proper procedure for removing a LOTO device when the device owner is not availible to remove it.

Torch and Welding Hot Work Permit - List items that need to be addressed prior to cutting and welding to prevent fires in the workplace.

Need for PPE on Tasks Checklist - Assist employers in determining which areas of the body may need PPE depending on the tasks being performed.

PPE Assessment Form - Basic form list 'task', 'hazard', 'PPE recommendation'. A sample page is provided.

Crane Pre-Operational General Checklist - Provides a critical item checklist to the crane operator prior to operating.

Wire Rope Inspection Report - Part of crane inspection concerning the condition of wire ropes on cranes and other material lifting devices.

Daily Visual Overhead-Crane - Provides a basic checklist of critical crane items for operators to inspect.

Electrical Task Assessment Checklist - Provides a checklist from NFPA 70E to ensure all safety items have been addressed when the need to work on live electrical systems.

Silica Program - Model program to assist employers with high levels of Silica exposures with monitoring,record keeping and training

Hearing Conservation Program (Construction) - Assists employers in devoloping a hearing conservation program

Asbestos Exposure Program - This Asbestos Operations and Maintenance Program has been developed to eliminate and control hazards associated with asbestos containing materials located at your site.

Lock Out / Tag Out Program - Program to assist employers in ensuring employees are using procedures to isolate energy sources prior to maintenance and other duties of equipment in the workplace.

Confined Space Program - Sample Permit Required Confined Space program. Itentifying spaces, equipment used, employee responsibilities ...

Bloodborne Pathogen Plan - Provides employers who have employees with BBP exposures, a guide for all areas that are required to be part of a BBP exposure plan.

Flammable Liquids Storage - An employer guide to proper storage procedures for flammable liquids.

N-95 RESPIRATORY PROTECTION PROGRAM - State of Maine public sector employers who require n-95 respirators to be used are required to have this program in place. This is a guide to be in compliance.

Lockout Procedure for Dump Body Trucks - Example Lockout Procedure for Maintenance on Dump Body Truck

Sample Lockout Procedure for Front Loader - Lockout Procedure for Maintenance on Front Loader

Lockout Procedure for Water Pump - Detailed sample lock out procedure for a waste water pump.

Respirator Medical Evaluation Form - Appendix C to 1910.134: OSHA Respirator Medical Evaluation Questionnaire (Mandatory)

Overhead Crane Monthly Inspection Form - Items that are required to be checked on overhead mobile cranes provided by United States Crane Certification Bureau.

Lock out procedure annual review form. - Annual Lockout - Tagout Administrative review of detailed writen procedures of lockouts for equipment.

Lockout Tagout Training Form - Ensures that training has been received on the Mandatory Lockout - Tagout Program. Provides checklist of items to be trained on.

Facility Inspection Checklist (MS Word Version) - Provides guidance to employers for the periodic inspection of thier facilities.

Safety Training Sign Off Sheets - Provides needed documentation for employers to track employee training has been conducted.

Hearing Conservation Program (General Industry) - Policy to assist employers who are required to have a hearing conservation in general industry.

PPE Assessment Version 3 - Detailed box check off of tasks PPE needed.

Hydraulic Jack Inspection Checklist - Provides items to be inspected every 6 months to ensure safe and proper functioning of jacks.

Qualitative Fit Test Form (saccharine method) - This form is for fit testing tight fitting respirators using the saccharine method.

Pallet Jack Inspection Form - Items to be inspected on a pallet jack prior to operations at the begining of the shift.

Safe Operation of Forklifts (2) Daily Checklist - Daily checklist items for safe operation of forklifts.

Workstation Checklist - Helps identify risk factors contributing to work-related discomfort or problems at workstations.

Trench Inspection and Entry Authorization Form -

Daily Trenching Log -

Excavation Checklist -

Hepatitis B Vaccine Declination Form - Sample Hepatits B Vaccine Declination form the employer shall have a signed copy on file, if an employee chooses not have the Hepatitis B Vaccine.

Hepatitis B Vaccination Employer Record - Employer record of employee hepatitis B vaccinations or declination.

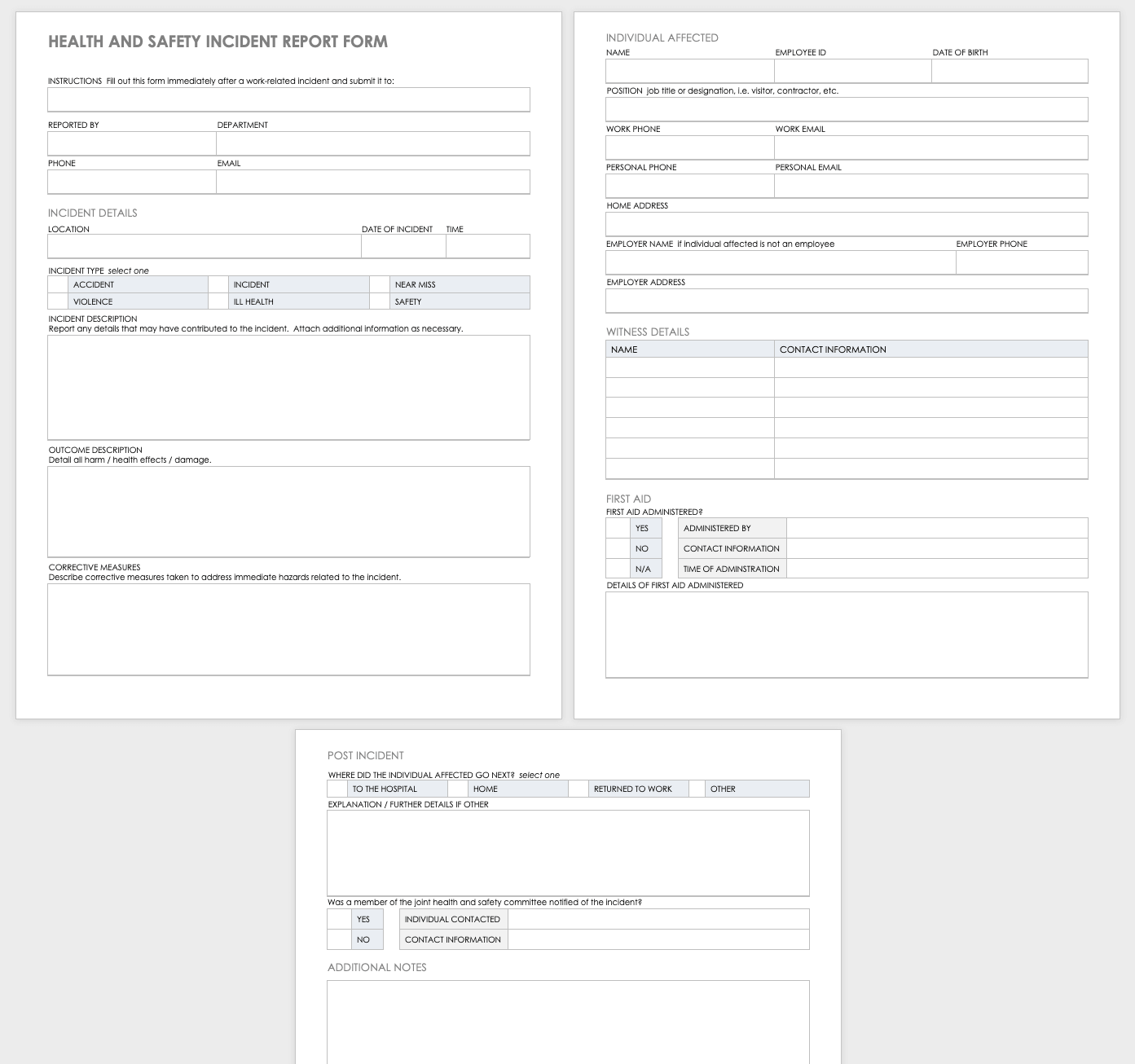

Maine's 301 Injury Illness Incident Report - If there is a pubic sector injury or illness incident that needs to be reported, and the workers compensation first report of injury is not available, this form may be used.

Employer's Report of Occupational Injury or Disease - First report of occupational injury or disease form. Source: Workers' Compensation Board

The OSHA web page has links to more sample safety and health programs!

This Occupational / Workplace Health and Safety Policy template is ready to be tailored to your company’s needs and is designed as a starting point for establishing employment policies on occupational health and safety, or OHS. A Workplace Health and Safety Policy may also be referred to as an Occupational Health and Safety (OHS) policy

What is an occupational health and safety (OH&S) policy?

Policy brief & purpose

Our Occupational / Workplace Health and Safety Policy help us preserve the best possible work conditions for our employees. Every employee has a right to feel safe at work. Our company is committed to follow legal standards and create a hazard-free workplace.

Our Occupational / Workplace Health and Safety Policy help us preserve the best possible work conditions for our employees.

Scope

This Occupational / Workplace Health and Safety Policy applies to all prospective and current employees of the company as well as volunteers, contractors and consultants.

Policy elements

There are two aspects to consider when establishing an Occupational / Workplace Health and Safety Program: Preventative Action and Emergency Management.

Preventative action

Preventative action is any action we take to avoid injuries or illness related to workplace conditions.

We’ll conduct periodical risk assessments and job hazard analysis to discover what is likely to harm employees. We’ll establish preventative measures accordingly.

Potential threats and dangerous situations include but are not limited to:

- Performing tasks on heights, scaffolds, ladders and other unsteady structures

- Chemical substances (toxic, flammable etc.)

- Operating dangerous equipment

- Slippery or uneven surfaces

- Electrical infrastructure

- Noise/temperature

- Quality of air

We’ll take the following preventative measures:

- When employees work in dangerous contexts or locations, we’ll make sure there are safety precautions like safety nets and ropes.

- We’ll provide protective gear like gloves, protective uniforms, goggles etc. Using safety equipment is obligatory.

- Inspectors and quality control employees will inspect equipment and infrastructure regularly

- We’ll hold employee training sessions in health & safety standards and procedures.

- All highly dangerous job tasks require at least two employees to be present

- Exposure to chemicals and radiation will not exceed a certain time limit

- Employees who do repairs or cleaning need to put up caution signs

- We’ll prohibit smoking indoors

Also, we’ll enforce a substance abuse policy to protect employees from colleagues’ misconduct.

Free Safety Program Templates

Emergency Management

Emergency management refers to our plan to deal with sudden catastrophes like fire, flood, earthquake or explosion. These depend on human error or natural forces.

Our emergency management involves the following provisions:

- Functional smoke alarms and sprinklers that are regularly inspected by [maintenance supervisor]

- Technicians (external or internal) available to repair leakages, damages and blackouts quickly

- Fire extinguishers and other fire protection equipment that are easily accessible

- An evacuation plan posted on the walls of each floor and online

- Fire escapes and safety exits that are clearly indicated and safe

- Fully-stocked first-aid kits at convenient locations

We’ll also schedule fire drills and emergency evacuations periodically. We will monitor performance of health and safety procedures and will revise them to ensure higher level of protection.

Additional measures

Our company will also keep abreast of changes and try to promote health & safety actively. We will:

- Update our policy according to changes in occupational health and safety legislation.

- Use incentive actions for health & safety (e.g. presenting safe employee awards.)

- Analyze past incidents to discover what went wrong.

- Establish clear procedures for accident reporting.

- Revise work procedures to make them safer.

Our company will also consult experts or insurance representatives to ensure it complies with local and international standards.

Free Safety Programs For Construction

Disciplinary Consequences

Every team leader is responsible for implementing this health and safety policy. Employees should follow health and safety instructions and will be held accountable when they don’t. We’ll take disciplinary action that may extend to termination when employees consistently disregard health and safety rules.

It’s everyone’s responsibility to contribute to a healthy and safe workplace.

| Disclaimer: This policy template is meant to provide general guidelines and should be used as a reference. It may not take into account all relevant local, state or federal laws and is not a legal document. Neither the author nor Workable will assume any legal liability that may arise from the use of this policy. |

Further reading

Need a single platform to manage the hiring process?

Workable is all-in-one recruiting software. Source and evaluate candidates, track applicants and collaborate with your hiring teams.

Construction Safety Programs Free Downloads

Get startedLet's grow together

Start hiring now with a 15-day free trial. Or talk to us about your hiring plans and

discover how Workable can help you find and hire great people.